Solutions

- TOP

- Solutions

- Partner Solutions

- Phoenix Contact PLCnext

Phoenix Contact PLCnext

DeviceGateway for PLCnext

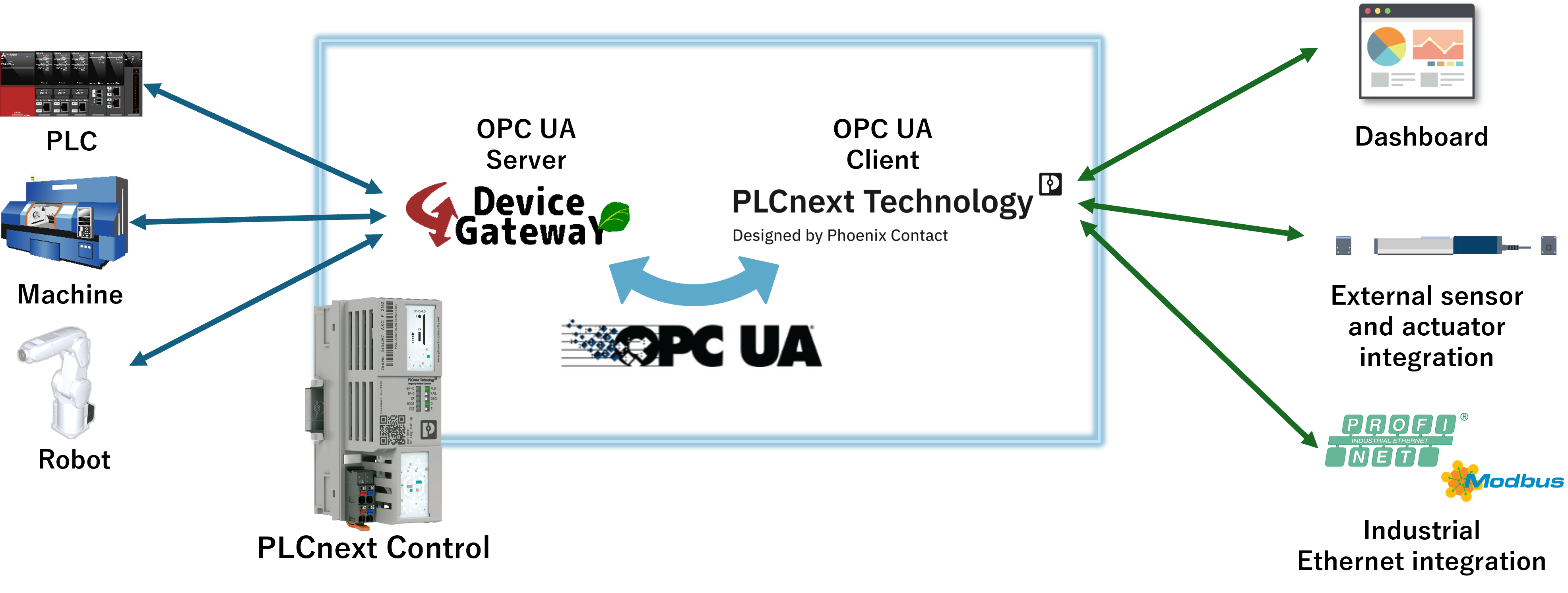

Takebishi’s DeviceGateway is now available for use on Phoenix Contact’s PLCnext Control. By installing DeviceGateway on PLCnext Control, you can achieve both high-speed data processing in an edge computing environment and efficient data integration with IoT systems.

Phoenix Contact PLCnext Control

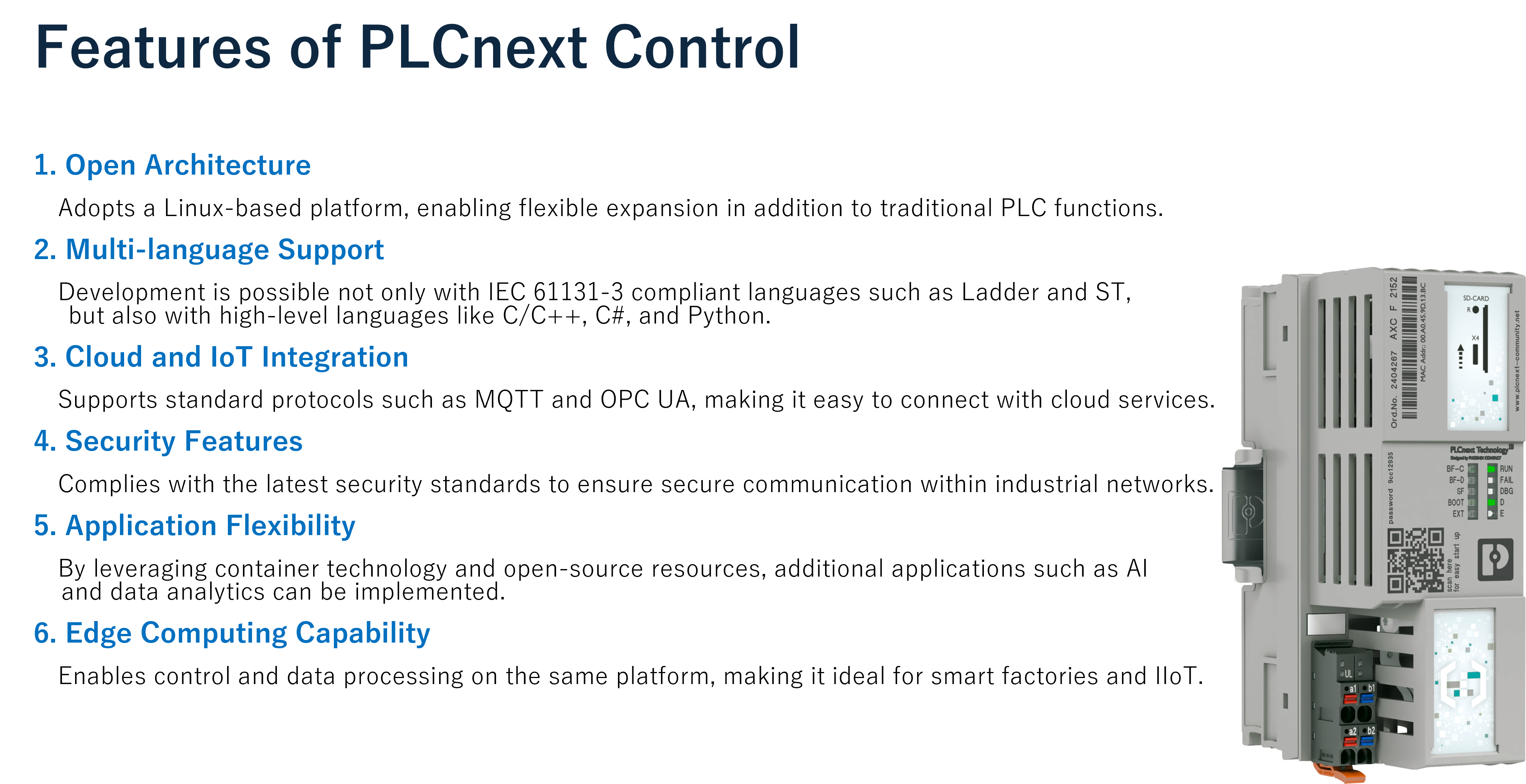

Phoenix Contact’s PLCnext Control adopts a Linux-based open architecture, offering flexibility and scalability ideal for industrial IoT and smart factories, including cloud connectivity and security features.

One of the key features of PLCnext Control is the ability to develop not only with IEC 61131-3 standard PLC programming languages but also with high-level languages such as C++ and C#. This enables collaboration between control engineers and IT engineers on the same platform. Additionally, it comprehensively supports functions required in the Industry 4.0 era, such as cloud connectivity using MQTT and OPC UA, implementation of AI/machine learning algorithms, and real-time data analysis.

Figure 1: Features of PLCnext Control

High Security for Driving On-site DX

When promoting on-site DX, security becomes the most critical challenge alongside data integration. The convergence of edge domains with IT and IoT systems significantly increases the risk of cyberattacks.

PLCnext Control complies with the international cybersecurity standard IEC 62443 for industrial control systems. Its development process is certified under IEC 62443-4-1, and the product is certified under IEC 62443-4-2, implementing OT security best practices such as authentication, encryption, and access control. Furthermore, it is effective in meeting EU Cyber Resilience Act (CRA) requirements, providing a robust foundation that satisfies global security standards. Meanwhile, Takebishi’s DeviceGateway, running on PLCnext Control, standardizes data from equipment of different manufacturers and ensures secure integration with IT systems. Communication between the two uses OPC UA, guaranteeing secure data exchange through mutual authentication and encryption. This accelerates DX while maintaining data integrity and confidentiality from the shop floor to the cloud.

Figure 2: PLCnext Control devices certified for IEC 62443-4-1 and IEC 62443-4-2 (from left: AXC F 1152, AXC F 2152, AXC F 3152)

Benefits of Integration

The integration of PLCnext Control and DeviceGateway provides a powerful foundation for real-time utilization of on-site data, going beyond simple data collection. Thanks to PLCnext’s open architecture, diverse equipment data acquired by DeviceGateway can be seamlessly integrated with AI and machine learning models, as well as cloud services.

This creates the following value:

- Predictive Maintenance

Analyze operational data to detect early signs of failure. - Productivity Improvement

Optimize control using real-time data. - Visualization via Dashboards

Instantly share necessary information from management to the shop floor. - Support for Global Deployment

Easy integration with overseas sites through security compliance and standard communication protocols.

Thus, the combination of PLCnext Control and DeviceGateway functions as a “data utilization accelerator” for realizing smart factories.

Figure 3: Image of PLCnext Control and DeviceGateway integration

Conclusion

By integrating Phoenix Contact’s PLCnext Control with Takebishi’s DeviceGateway, essential functions for promoting on-site DX—such as equipment data collection, integration, processing, and dashboard creation—are provided on a single platform. This enables companies to advance DX globally while maintaining compliance with international security standards.

Related Products and Services

Takebishi:DeviceGateway

Phoenix Contact:PLCnext (external link)

Available from PLCnext Store: PLCnext store (external link)

PLCnext × Easy Integration Accelerates On-site DX (Overview) *Japanese:(external link)