Solutions

- TOP

- Solutions

- Case Studies

- External Configuration Function

External Configuration Function

Unlocking Dynamic Automation: Transform OPC Server Configuration

In the age of smart manufacturing and digital transformation, industrial systems must be more agile, integrated, and responsive than ever before. Takebishi’s latest release of DeviceXPlorer OPC Server v7.4.2 introduces a powerful new capability that meets these demands head-on: external configuration capability. This feature allows external applications to dynamically create, delete, and modify communication parameters and tag configurations for devices - ushering in a new era of Dynamic automation.

Engineering Efficiency with External Configuration

Implementing data systems in factories can be time-consuming, as each machine may use its own communication protocol. Previously, avoiding data silos required manual workarounds or complex systems developed by specialized engineers, which did not scale well and failed to anticipate future data accumulation trends. The new GUI-based input of commands and responses allows the transmission of packet contents without specialized knowledge. The readability of these user-configured protocols also enhances scalability for various systems and use cases, with JSON files that can be reused at other locations.

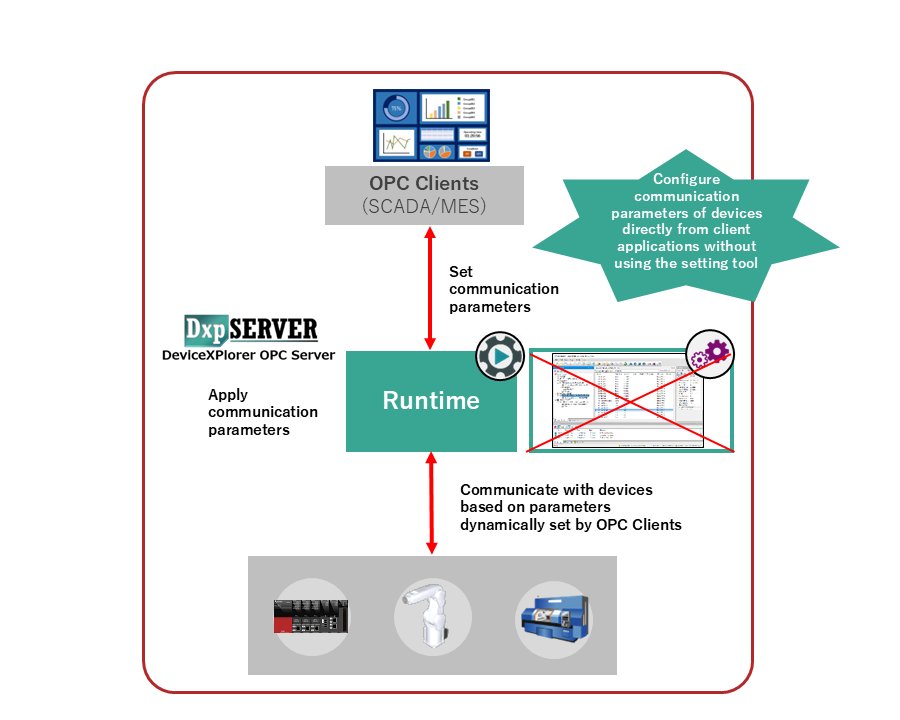

DeviceXPlorer OPC Server has introduced new system tags that expose internal device communication settings to external applications. Previously, configuring DeviceXPlorer OPC Server requires manual input through the dedicated setting tool. With this update, external systems - such as SCADA (Supervisory Control and Data Acquisition) platforms, MES (Manufacturing Execution System) software, or custom applications - can now handle the configuration of DeviceXPlorer OPC Server such as:

- Create, update, and delete tags

- Create, update, and delete communication parameters with devices

- Backup and update the configuration file

This shift from manual to dynamic configuration dramatically improves operational efficiency. Engineers can now automate setup processes, synchronize configurations across multiple systems, and respond to changes in real time - all without using the dedicated setting tool.

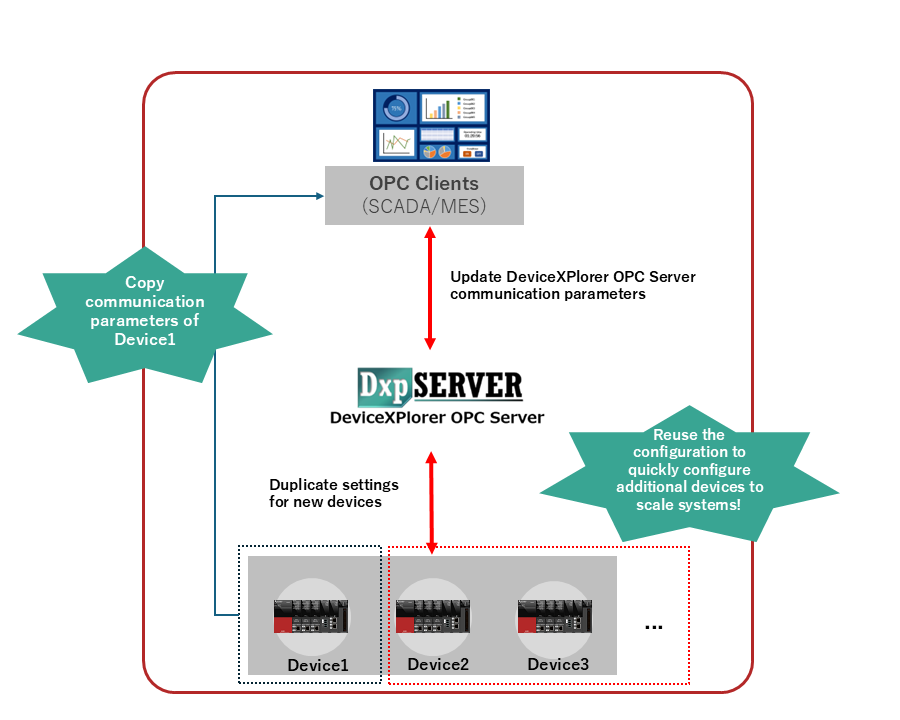

To illustrate, imagine a production line where new devices are added regularly. Instead of manually configuring each device’s tags with the dedicated setting tool, the configuration for the new devices can be quickly integrated from external applications. Configuration of multiple devices using various external automation technologies ensures consistency across devices, a must for scalable systems.

Agile Configuration for Scalable Data Solutions

The implications of this feature go far beyond convenience. It represents a fundamental shift in how industrial systems are managed and integrated. By enabling external control over server configurations, this new feature can bridge the gap between operational technology (OT) and information technology (IT).

In essence, the external configuration capability can make DeviceXPlorer OPC Server not just a communication software, but an active participant in the automation ecosystem.

Beyond engineering efficiency, the external configuration capability unlocks strategic value for SCADA and BI tool vendors. By embedding DeviceXPlorer OPC Server’s configuration interface directly into their platforms, vendors can offer users a unified experience, thereby eliminating the need to switch between separate tools for communication setup. This integration enables users to configure devices and establish communication flows entirely within the SCADA or BI environment, streamlining workflows and reducing setup time. It’s a game-changing enhancement that transforms DeviceXPlorer OPC Server into a collaborative component of modern industrial software ecosystems.

Conclusion

The introduction of the external configuration capability in DeviceXPlorer OPC Server v7.4.2 is more than a technical enhancement - it’s a strategic enabler for the future of industrial automation. By allowing external applications to manage server configurations dynamically, DeviceXPlorer OPC Server empowers organizations to build systems that are not only smarter but also more resilient and scalable.

This feature aligns perfectly with the goals of Industry 4.0: interoperability, automation, and data-driven decision-making. It reduces the friction between systems, simplifies deployment, and enhances the ability to respond to change. Whether you're managing a single facility or a global network of industrial sites, the external configuration capability offers the flexibility and control needed to thrive in a connected world.

Discover how Takebishi can transform your manufacturing communication today!